Newsletter April 2021

President's Message

Free software that can create Japanese Wood Joinery

I found an article in Spoon & Tamago, a blog that covers Japanese design, about some researchers at Tokyo University who have created a software program that can be used to develop diagrams and CNC software for complex Japanese woodworking joints. These are joints that do not need any glue or screws, etc. (known as "tsugite") See Note below.

This may be good news as I have struggled, and mostly failed, to consistently cut tight-fitting Chinese joints.

Every year at the annual Kezurou-kai event there is a demonstration where a Japanese woodworker spends most of the day cutting shallow-angled slopes on 2 long pieces of wood about 12 x 6 in. square. Finally, when he has finished cutting, he slides the 2 pieecs together for the first time and with the aid of a very big mallet closes the joint tight. He then hammers a 1/2 in. square key into a grove cut between them and there is a solid, locked, sliding lap joint.

BAWA Member Yeung Chan gives presentations when he brings a table or a chair to our meeting in a flat box then assembles it by pushing the pieces together and locking everything in place with a ¼ in. square key. At the end of the night Yeung removes the key, disassembles the piece and puts it back in its box - always an impressive

demonstration.

The Tokyo University software has a library of pre designed joints plus the ability for you to design your own.

Is the future that we will cut and prepare pieces of wood, take them to a shop where we can rent time on a CNC machine to mill the joints and then take them back

home to finish the project? The only drawback is that we will have to live with rounded edges on our joints as milling machines use rotating cutters, but when the piece is finished most joints are invisible anyway.

Note: I am not sure that there is difference between Chinese Wood Joints and Japanese Wood Joints so in these notes I have treated them as interchangeable. [I think the difference is that Chinese woodworking focuses on making small things (ie: furniture) so uses small joints and the Japanese woodworking focuses on making big things (ie: Temples) so uses big joints. Big or small the basic joint structures are the same.]

For more information: spoon-tamago.com/2021/04/08/tsugite-wood-joinery-software

Frank

(Contact at:

Frankramsay8@aol.com

Top

April 2021 BAWA Zoom Meeting

Before the meeting started we discussed how we might get a Zoom setup for the meetings when we can meet in person. (Roland Johnson was named as a possible source for more information.)

A number of members mentioned that they would like to meet in person again when the time is right.

Announcements:

The meeting was called to order by President Frank Ramsay.

Guests:

Jerry Cousins of Weaverville said he was into marquetry.

Ed Kelly of San Francisco said he was into furniture making and he recently got into turning.

Jeff Thompson of Salinas is into 18th and 19th century furniture.

Ed Kelly has a new Oneida Super Duty Dust Deputy 6" for sale.

It retails for $240, he will sell it for $150 to any interested member.

(Details have since been sent out in an email blast)

We had 37 people join us in this Zoom session.

The next meeting will be on Sunday, May 16th

Top

Featured Speaker

BAWA Member Ken Napoir

Reproducing Antique Furniture.

To reproduce antique furniture Ken says start with research - find a book or two.

Beginners should start with simpler projects like Arts & Craft style pieces.

The intermediate woodworker can do period pieces.

It retails for $240, he will sell it for $150 to any interested member.

(Details have since been sent out in an email blast)

BAWA Member Ken Napoir

Reproducing Antique Furniture.

Queen Anne style Secretary he built in 1991

Knee Hole Desk

Methodology

Pick a nationality, pick a period, pick a style.

Successful design depends heavily on proportions. Use the Golden Mean when designing your piece.

Ken mentioned Mack Headley: he has written articles for Fine Woodworking on carving features for period furniture.

He showed a photo of a Queen Anne style Secretary he built in 1991. He also showed the dimensioned drawing he made for it.

He brought up a couple of points that are important when putting together a piece.

1. Match the wood grain pattern across the piece.

2. Allow for seasonal wood movement.

3. Make sure the case is square before the glue sets up.

4. Moldings add to the appearance.

5. Use patterns for legs and moldings

.

Chippendale Tea Table

Queen Anne Tea Table

Ken's pieces often have ball and claw feet, frets up top, and fluted columns along the side. It takes time to learn to carve the ball and claw features.

He recommended Horton Brasses, Inc. for hardware.

Bruce Powell recommended a book by Gustav Ecke: Chinese Domestic Furniture in Photographs and Measured Drawings.

Top

Virtual Workshop Tour

Surface prep for finishing

The Virtual Shop Tour was all about surface prep and finishing.

Burt Rosensweig

Burt showed his DeWalt random orbit sander, a rubber hand sander

and a simple block of wood that he said was so easy to use for sanding.

BrucePowell

Outdoor drying rack

Jamie Buxton

In use

Stored on wall

Wheels

Neal White

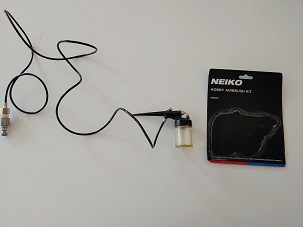

Simple spray gun for use with workshop compressor

Top

Show and Tell

Burt Rosensweig

Burt showed the table saw miter gauge stop block he made

from steel rod and aluminum rectangle stock.

Minutes by Burt Rosensweig, Secretary

Top

from steel rod and aluminum rectangle stock.