Newsletter June 2019

Presidents Message

Fellow woodworkers

While we were on vacation we visited the Kunsthaus Museum in Zurich. It was known for having 3 very large, very impressive, Monet paintings - the kind of paintings you could sit and look at for hours. Unlike most museums that I have visited these priceless paintings were hanging on the wall without barriers of any kind.

The museum had a beautiful art-deco styled interior. I was surprised when we came across a room lined with a pre-art-deco interior that came from an old house.

But at this stage my description comes to a halt. We did not purchase the museum catalogue as it took a long time to go round it and when we returned to the lobby area the main book shop had already closed and I just assumed I would be able to look-up the room on-line. So far no luck. There are 100s of pictures on-line that visitors have taken of the paintings in the museum but nobody photographs the woodwork!

Enjoy your woodwork Frank (Contact at: Frankramsay8@aol.com)

Top

Last Meeting

The meeting was called to order by Membership Chairman and Treasurer John Blackmore due to the absence of both our President and Vice President.

Upcoming Meetings:

June 16th: Jamie Buxton will present a special Show and Tell about cabinet building plus we will have the

2x4 challenge.

July 21st: Tom Gaston will speak about carving.

August 18th: Tom Vogel will speak about Kumiko Zaiku.

September 16th: Currently still open. Frank is trying to arrange a talk on finishing.

A talk was requested on how to cut and dry lumber.

Announcements:

Bruce announced that the final silent auction on the Gerald Sellers tools will take place tonight.

John Blackmore announced that we now have 46 paid members.

Ed Schoenstein announced that he has a metal cutting bandsaw to give away.

Top

Bruce announced that the final silent auction on the Gerald Sellers tools will take place tonight.

John Blackmore announced that we now have 46 paid members.

Ed Schoenstein announced that he has a metal cutting bandsaw to give away.

Top

Featured Speaker: Jon Kaplan on CNC routing

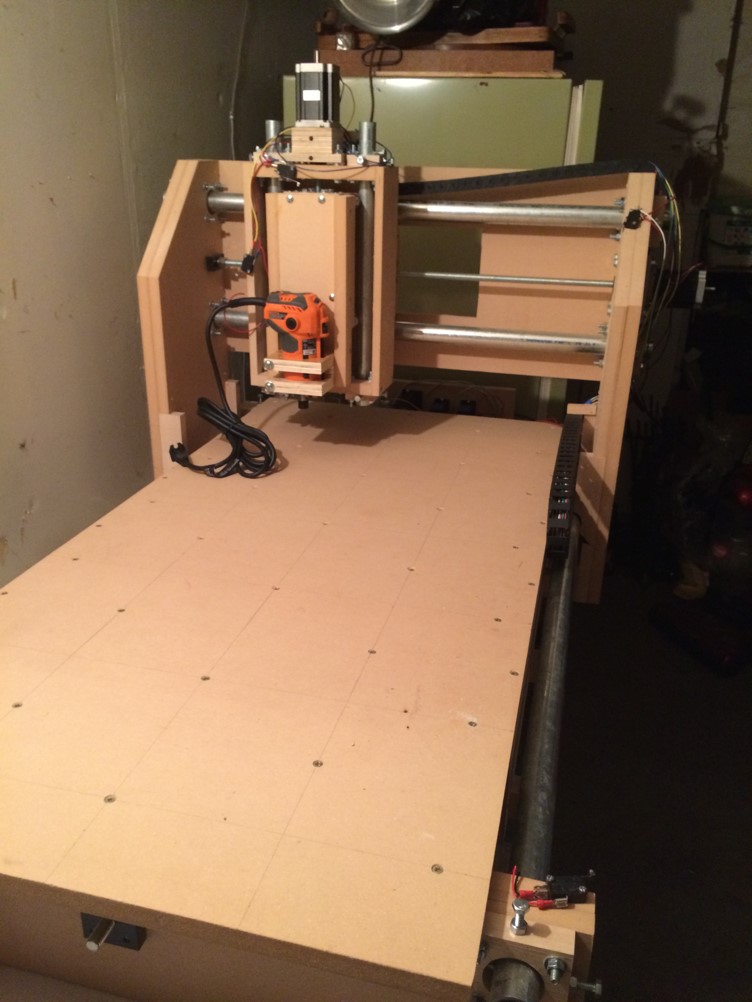

John introduced our first speaker, Jon Kaplan, whose topic was CNC routing. Jon has a background in electrical and mechanical engineering. He has spent 40+ years working in product design, first designing Polaroid cameras. In 1988 he moved to California and worked for 2 startups and then IDEO, where he has now worked for 27 years. He started CNC woodworking at the Tech Shop using their large ShopBot machine to make a wooden plaque for his synagogue. He built his own CNC router in 2015, holding the total cost of materials to under $1000. He designed it with Sketchup, and, using common materials such as MDF and gas pipe, built it in 5 months. The large gantry on his machine is driven by a single leadscrew, but he decided later that twin leadscrews would have been a superior design. The working area is 18"x32" with 4" of z-axis motion. Jon primarily uses 1/8" or 1/16" metal cutting endmills, which are much cheaper than router bits.

CNC Table parts

Completed machine

There are many computer aided design (CAD) programs available which can be used to create the computer model of the part to be fabricated. The next step, CAM, generates the G-code instructions that are needed to drive the stepper motors in the device. Sketchup is a free and easy to use CAD program, but it is not parametric. OnShape is also free (for a limited amount of data storage) but is only usable online as it is cloud based. It is parametric and has an active online community. FreeCAD is open s source. Jon now uses Fusion360 which is parametric and is free for hobbyists and small businesses. It has built-in CAM capability, allowing you to specify material size, cutting paths and tools, speeds, direction of cut, etc., and generates the G-code. Jon then demonstrated the value of parametric modelling by modifying the door dimensions on a cabinet design and showed that all the dimensions of the cabinet were changed as a result, allowing much quicker design changes. Jon then described the process used in cutting the wooden gears for his clocks. He considers how the part is held down during machining, cutting speed, depth of cut per pass, etc. He uses climb cutting to ensure that too much material is not removed from the part. He does the rough cutting, leaving the part .015" or so oversize, then does a final pass to the finished dimensions.

Jon provided a list of basic online resources for CNC information:

diy-cnc-beginners-getting-started-cookbook

Popular Woodworking video

Free 5 Day Crash Course in CNC

Synagogue logo

Clock gears

Jon showed many examples of commercially available CNC machines, ranging from a Sainsmart Genmitsu CNC 3018 kit costing $250 up to a 4'x8' ShopBot machine with automatic tool changer for $45,000. A couple of examples of different approaches to CNC machines are the Maker Made CNC Maslow which stands vertically and is 2D only, but has a 4'x8' working area, for $500, and the Shaper/Origin handheld CNC router for $2,500. With this handheld machine, the operator roughly follows the intended part profile and the machine corrects for any error, getting its position reference from guiding tape that was previously applied to the work piece. This would be especially useful for machining very large objects like floors or tables. Jon is considering upgrading to the Carbide 3D Shapeoko machine.

Why would anyone want to use CNC instead of a bandsaw, jig saw, or router? In order to make multiple parts of the same type or to machine complex shapes which would be difficult to cut on hand guided equipment.

Second Speaker: John Flaherty: Rebuilding after the fire

After a 15-minute break our second speaker, John Flaherty talked about the work he did to re-build the house he owned in Santa Rosa that was burned to the ground by the Tubbs Fire. He started the foundation on May 1, 2018 and was one of the earliest homes in his neighborhood to start construction. Then began the construction of 2x6 framing members. The great room has a high ceiling that is supported by exposed pre-assembled roof trusses that were lifted into place by a crane. John built all the cabinet carcases in his shop and delivered them on-site as they were finished. The cabinet fronts and doors are cherry. The floors are engineered material that is 7/8" thick rather than ¾". The finished house can be seen at 4540 Redwood Highway, Santa Rosa.

Before the re-build