Presidents Message

Fellow Members

BAWA is your association and we would like to hear from you. This is the time of year when our Program Chair, Per Madsen, starts to plan out the speakers and events for next year's program and he would like your input on what topics or speakers you would like to see on the calendar. This year we have had talks on tools, finishing and joinery plus topics as diverse as building tree houses and Chinese junks. Also this year most of our meetings have been held in Foster City which seems to be a good central location. But what would you like to hear about next year? Do you have any suggestions for speakers? Or maybe workshops we can consider visiting? Or classes we should try and arrange? If you have any suggestions for next year's calendar please send an email to Per: permads@comcast.net Your input will be helpful in planning another great set of meetings.

I would like to expand the Gallery section on our website as it is a great place to show our work. We have a great deal of talent in BAWA and over the course of our meetings we see a selection of members' work. But I know that many of you produce fine work which is not shown at the meetings because of its size, or the difficulty of bring it to Show and Tell.

I would like to ask you for pictures and a brief description of any work you would like to put in the Gallery so we can increase its scope. In exploring how to better present the work in the Gallery I started by trying to regroup my work in a more interesting way. Gallery Frank Ramsay If you provide me with your information I will update the other pages in a similar manner.

Just a reminder: if you have not yet submitted an entry for this year's 2nd Annual BAWA Show at Woodcraft on 21st - 23rd October it is not too late to do so. You can find further information and the on-line entry form at: 2011ShowInfo

Enjoy your woodworking.

Frank R Ramsay

President

frankramsay8@aol.com

New Members:

Frank Ramsay called the meeting to order at 7:00pm and asked that new members and guest introduce themselves. Three people stood and introduced themselves: Andy, Dan and John.

Announcements

Per Madsen asked that the members of BAWA think about possible topics for the monthly meetings. Several members have contributed with presentations in the past year: Mike Bray, John Blackmore, Claude Godcharles and tonight Harold Patterson.

The September meeting will feature John Levine, recommended by Mike Bray, to talk about joinery, Chinese joinery in particular.

Ed Marinaro presented some of the details of the upcoming BAWA 2nd Annual Woodworking Show to be held at Woodcraft, San Carlos on October 22-25, 2011. The judging panel will be composed of three BAWA members: Arnold Champagne, John McCormack and Mike Bray. Ed is seeking charitable donations for the show so that we may offer genuine prizes in addition to the ribbons. Donations will be tax deductible. A separate panel composed of Ed Marinaro, Claude Godcharles and John Blackmore will establish woodworking categories for the show. We will be publicizing the show and ideas and contributed effort will be welcome. Anyone have a Facebook page or blog? If so, use it to talk up the show. Several show committees have been formed to run the show and volunteers are needed. More information will be forthcoming. Jamie Buxton will be in charge of the 2 X 4 category for the show. Harold Patterson will be in charge of the toy category. Show entry forms can be found on the web site.

Harold Patterson will be holding a toy workshop on August 27 at Jamie Buxton's shop starting at 10:00am. The workshop will focus on making parts for the new race car designed by Frank Taylor. Scrap wood in contrasting colors, 3/4 in. thick is needed for this workshop. Bring in yours.

Mark Rand needs your Woodcraft receipts so that the club can get its rebate.

Ed Marinaro is donating an older Craftsman shaper to the club for a silent auction event.

Neal White is holding a hand plane class at the Woodcraft store in Dublin.

Harold Patterson

Routers and Accessories

Harold's prize winning box

Harold was born in Jamaica, grew up there and went to a technical high school where he learned to create and build things. His tool philosophy can be summed up as follows: Use tools for their designed purpose. He sees too many people inventing uses for tools, including routers, for tasks that they were not designed to perform.

Harold has dreams of moving to the East Coast, building a new house with a separate wood shop. Then his wife will really be able to use the garage. Sounds inevitable.

According to Harold, a woodworker needs three types of routers: a mini router, a trim router and a plunge router. The Dremel mini router can be fitted with a precision base from Stumack Company, a supplier to tools to luthiers. A sheetrock router can also be a useful mini router. The trim router typically does not plunge but can be fitted with a MicroFence plunge base available in the woodworking catalogs. It permits greater accuracy. Harold does not use fixed base routers, preferring to use plunge routers instead. He has several. He has a 2 1/4 HP Porter Cable in his router table that permits height adjustment from above with an adjustment knob. He has three other identical plunge routers, two for dovetails and one as a backup. Harold likes the MicroFence because it can be adjusted in 1/1000" increments.

Harold built his own router table fence because the commercial ones are not high enough. His is 7 inches tall and features sliding faces and a slot for feather boards and plastic inserts. He provides for dust collection above and below the table with a closed lower compartment. He said that the Rousseau inserts are not flush with the tabletop, so he makes his own table cutouts to ensure a flush fit.

Lots of routers

Safety is always of paramount importance. Use goggles, dust collection and a small Jorgensen clamp for holding small parts. Climb cuts can be useful, even desired, but you need to follow a few guidelines. Never climb cut with the work piece between the bit and the fence. You only invite a disastrous throwback. He first climb cuts the last 1/2 inch of a cut to avoid tear out when feeding the board into the bit. A climb cut can be useful to finish smooth a cut previously made feeding into the bit. He uses double-sided carpet tape to hold small pieces for routing. It is available at Home Depot. He always puts small pieces in a fence jig. A starter pin in a router tabletop should be used to ease wood pieces into the bit. It affords greater control and precision.

He uses several types of router bits: straight edge cutting bits, top bearing bits, slotting cutters and molding bits from MLCS. Everyone should have a 1/8" and a 1/4" slot cutting bit.

When making dados for shelving he prefers to use his router running inside two parallel strips joined with cross bars it either end. The width of the parallelogram can be adjusted to the width of the shelf dado. A top bearing straight bit will cut the dado and follow the pattern created by the jig rail of the parallelogram. Edge jointing can be done with the router by placing a thin plastic shim behind the out feed fence of the router table. The cut will be equal to the shim thickness.

A special passion of Harold is to combine his two loves: fly fishing and woodworking. He makes fly boxes and showed us a prototype he had entered into the Home Arts Woodworking category at the San Mateo County Fair. He won first prize and a blue ribbon. The special feature of his boxes is the lock mitre joint. There are some essential guidelines to follow if you want a perfect joinery. The bit height must be set to exactly 1/2 the thickness of the wood as must the distance of the fence from the bit. He uses a precut delrin blank set for wood thickness of either 1/2" or 3/8". He recommends the following process. First run the horizontal cut, flip the board and run it from the other side. If you have wood remaining, raise the bit. If you cut too deep, lower the bit. Then do the same thing for the vertical cut. Or otherwise, buy and use a height gauge available from Lee Valley. See the handout from Harold.

Harold makes his fly boxes in 22 steps. The lock mitre joint is strong, always sets at 90 degrees and looks great. He cuts and arranges his front, back and side pieces so that the grain runs continuously around the box. For the top and bottom, he uses 1/8" 3 ply plywood that he laminates veneer onto both sides, ending up with a 5-ply piece. He cuts a rabbet into the box sides to accept the top and bottom with an exact flush fit. He glues it all together, then makes a full perimeter cut, leaving only a sliver of wood that he later cuts out with a scalpel. He uses formaldehyde glue, and magnets for lid closure.

Harold's latest box was made to present to the Fly Tier of the Year. It was made in the shape of a seashell from old growth redwood burl, shaped on the band saw then hand carved. It is finished with a mixture of linseed oil, tung oil and polyurethane.

The prize winning box

It was getting late, so Harold summed it up and we moved on to Show and Tell. We all learned a lot about routers, accessories and especially how to make a good lock mitre joint.

Frank Ramsay made a Chinese style end table to match the table he had made earlier. Frank made all the joints on his table saw using the Yeung Chan method. The base is mahogany, the top bird's eye maple with a strip of Indian rosewood. The sides are a walnut grid pattern holding maple ovals.

Ed Marinaro had made a music stand for last month's 2 X 4 contest, but could not attend the meeting. Otherwise he would have won. The desk portion of the stand is fully adjustable in height and can be rotated from a low to a high position. The center column also permits height adjustment. Ed lamented the performance of the locking mechanism for the desk and vows to improve it.

Ed's 2x4 Music stand

Arnold Champagne is making a computer stand for a client out of white oak. One side of the frame is curved, made from 12 laminations of white oak. Arnie made a molding frame jig, then practiced the gluing and assembly process in dry runs until he was confident he could set up each curved piece in the jig within 5 minutes. Practice your process, he said. He used West Marine 205/2306 epoxy because it sets up solid and does not creep as is the case with the yellow wood glues. He used 22 clamps on each assembly.

Arnold's bending jig

Jay Perrine attended the Northwest Woodworking Studio class on chair making taught by Michael Fortune from Canada. He was the only student to complete his prototype chair during the one-week class. We look forward to seeing the finished chair set before Christmas, maybe even in time for the Woodworking Show.

Jay's prototype chair

And saving the extraordinary for last: Frank Taylor is making a toy wooden locomotive. He showed us the preliminary model, but plans to enlarge the cab section slightly. It looks to be an authentic reproduction of a steam locomotive. He plans to make the accompanying coal tender and has challenged his fellow BAWA club members to make cars for the train-flat cars, boxcars and tank cars. Frank will make the wheels for anyone wanting to make a flat car. Then the entire train can be displayed at the Woodcraft Christmas showing, perhaps even auctioned off to raise money for charity. This project deserves our special attention. Apply your Sketch-Up skills, recruit your BAWA member friends and let's make a train.

Frank's train

We adjourned late and satiated with great woodworking information and techniques.

John Blackmore

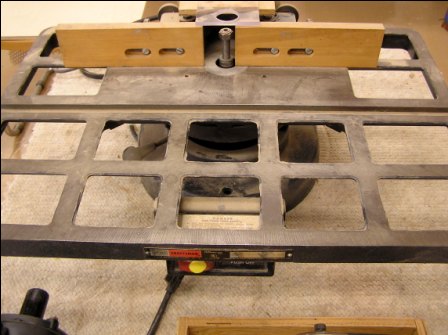

One of our members, Ed Marino, has given a Sears Craftsman Shaper to the Association for a Silent Auction. All money raised will go to the Association. (see details below)

The form of the Silent Auction is:

Members should email their bids steve@rosenblums.us

Closing date for bids is 8.00 pm Sunday September 11th.

No phone calls for bidding will be accepted.

You will be notified by email if you are the winner.

If you would like to know the current highest bid then email Steve.

Minimum bid is $75

This table shaper was purchased in 1989 and used in a home workshop. It has never received heavy use due to the availability of time to do woodworking and the type of projects undertaken.

SECIFICATIONS

Model number 113-23930 Sears Craftsman includes original manual.

Overall size 27" x 28" x 8"

Table top 19" x 27" x 1 1/4"

a. machined cast iron

b. 3/4" Miter gauge grove

c. overhead arm for free hand shaping

d. adjustable slit fence with replaceable wood face

Motor

a. 1/2 hp

b. 3450 rpm 115 VAC 60 hz

c. capacitor start

d. mounts at rear, hanging off of base plate with belt drive

e. front mounted push pull locking power switch

Base 21" x 12" x 2"

a. Cast iron with bolt holes for attaching to table or bench top

Cutters all in good condition or not used

a. 1/2" arbor

b. 16 high speed steel Craftsman original set

1/4" and 1/2" slotting

1/4" matched t&g set

1' straight

1" glue line

3/4" cove

3/4" 1/4 round 1' ogee

3/4" tongue

1" interlocking

3/8" door lip

additional coves various shapes

c. 1 - Rockwell 3902 vertical panel raising, carbide tipped shaper cutter with 3/4" bore and 1/2" bushings. Never used.