Newsletter November 2020

President's Message

We went for a walk in the Reinhart Redwood Regional Park a few days ago. It is on Skyline Blvd., a 20 minutes drive from downtown Oakland.

The park is so close to the densely populated Bay Area yet once inside the sounds of cars disappears and you feel that you are miles from anywhere. It is very hilly, straddling a long ridge, covered with trees and large ferns criss-crossed with trails

Redwood Regional Park was established in1939, In 2019 it became the DR. Aurelia Reinhardt Redwood Regional Park, in honor of the doctor's early work and efforts in helping to establish the East Bay Regional Park District, Dr. Reinhart was also president of the nearby Mills College

The ancient coastal redwoods that once stood in the East Bay were thought to have been some of the largest, possibly reaching 30 feet across. They blanketed the hills of Oakland and were used by ships to navigate through the bay. The hills were the home of the Ohlone and Bay Miwok people.

In the mid 1800s the area was heavily cleared of its redwoods to feed the many nearby sawmills whose timber help build San Francisco and the other new cities of the area Even the stumps were removed for firewood and shingles.

The redwoods still standing are 3rd growth trees but still over 100 years old and 100 ft, feet high.

You can hike amongst them and the other trees in total isolation, virtually never seeing or hearing any of the outside bustle.

There was also a small thicket of Blackberry bushes where a swarm of Ladybirds gather every year

We picked up a leaf from a Big Leaf Maple tree

Could be used as for marking miters as the

veins form perfect 45 and 90 degree lines

Across Skyline in the Leona Heights Park there is the one Coastal Redwood "Old Survivor" still growing. It is about 500 year old and only survived the axe as it is "next to an exceptionally steep and rocky slope" so difficult to reach - it is on the list for another challenging walk

The park has several entrances along Skyline. We entered the park for a 2 hour stroll and ended up spending over 4 hours in the park – I suggest you carry a more upto date trail map than we did.

Fellow woodworkers,

Enjoy your woodwork Frank (Contact at: Frankramsay8@aol.com)

Top

November 2020 BAWA Zoom Meeting

The meeting was called to order by President Frank Ramsay.

Announcements:

Treasurer Jon Kaplan announced that dues need to be paid to him by check. Dues for 2021 will again be $48. Jon will look into online payment methods.

Matthew Werner identified himself as a guest who does marquetry.

The next meeting will be on December 13th.

Following the talk, Burt Rosenzweig volunteered to take on the secretary duties for BAWA. (Steve> As outgoing secretary of 10 years standing, I wish him well and offer my support in the future.

Top

Guest Virtual Speaker

Brian Newell

Brian had spoken to us previously in 2011. He makes original furniture designs which he will be showing this evening as well as providing a tour of his shop.

Brian was born in Flint, MI in 1966 and began woodworking at the age of eight, doing carving. He recommends it as a good way to explore wood as a material to learn about how to cut grain properly.

At 14 he began to read books, starting with "A Cabinetmakers Notebook". After reading Krenov's book he purchased a jointer and a bandsaw. He then began attending the University of Michigan in order to avoid a life of manual labor, but soon found himself immersed in the camaraderie of the university's woodshop.

He did not graduate but began attending the Krenov School in 1989. He found the folks there to be "smart people working with wood" who validated his choice of woodworking as a career. He left the school at the age of 21 and went to Chicago where he worked making patterns in basswood for the model automobile industry. There he learned how to make smooth compound curves for body work as well as crafting small details.

He then went to Japan for 10 years where he made and sold furniture through studio galleries.

In 2008 the gallery furniture business fell apart. Nowadays he mostly does work on commission.

He purchased the Cypress Street Barn in partnership with Jennifer Anderson. They remodeled it and now have 5 renters of shop space. The total floor area is 3200 square feet and includes a gallery/office space. After working on the renovations for several years Brian is now able to go back to working on furniture.

>

>

Among the pieces he showed were:

Pearwood cabinet from the early 90's with coopered doors and carved cocobolo decoration. It is a Krenov-like piece, but with carved decorations.

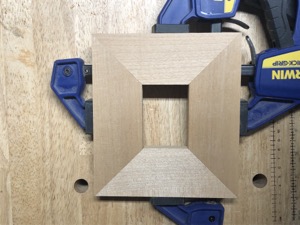

Sycamore and hornbeam cabinet, which is meant to be a "walk around piece". It is about 5 feet high and has glass shelves, and a base with mitered corners reinforced with splines.

Rosewood and Applewood box which was the first piece he made in Japan. The lid is frame and panel construction, curved and domed. He generally works without drawings, preferring to make sketches and then building templates to construct the final piece.

Curved, veneered cabinet in which the Imbuia wood veneer is cut in small squares to conform to the curved surface.

4-1/2-foot-tall curly sycamore cabinet. The cabinet is formed of 6 identical curved panels, made by laminating commercial veneer, bent over a form in a vacuum press. The sycamore veneer is applied in 5 rows over the curved substrate. The show veneer is custom sawed about 1/16 inch thick. The glue used was Unibond. He cautioned never to use a water-based glue when veneering as this causes the veneer to swell. Rather, one should use epoxy or urethane.

Rosewood cabinet with Ebony legs with veneered squares. The lower stretchers are bent lamination. The piece was veneered one row at a time in order to get the joints tight.

Ebony and rosewood desk in the form of a half circle. It has laminated panels and 9 Ebony legs.

Brian then gave a shop tour.

The shop has 6 bench spaces with an 1800 square foot machine room. The equipment includes a Laguna dust collector, an Oliver 88 sliding table saw, a Sawstop cabinet saw, a 24 inch Oliver planer, an 8 inch Delta jointer with a helix head, a vertical belt sander, a spool sander to cut inside curves, a 20 inch Kuwahara jointer, a 30 inch Oliver bandsaw with a 1/2 inch blade, a 36 inch Oliver bandsaw with a 1 inch blade for cutting veneers, a 16 inch Powermatic, a Hoffman horizontal mortising machine and a chop saw.

The gallery is a long narrow space where he holds winter shows for the Krenov school.

Top

Virtual Shop Tour

Bandsaws

Coordinated by Paul Krenitsky

Results of the highly un-scientific BAWA bandsaw survey

Which do you own?

Neither a bandsaw or a tablesaw: 4.3%

A bandsaw, but not a tablesaw: 17.4%

A tablesaw, but not a bandsaw: 0%

Both a bandsaw and a tablesaw: 78.3%

If you could have only one, but not

the other, which would you prefer?

Bansaw, but not a table saw: 72.7%

Tablesaw, bur not a bandsaw: 27.3%

A bandsaw, but not a tablesaw: 17.4%

A tablesaw, but not a bandsaw: 0%

Both a bandsaw and a tablesaw: 78.3%

Tablesaw, bur not a bandsaw: 27.3%

John Wilson

John has a Minimax 16 inch saw with a 1/2 in. inch carbide blade.

It has 4" dust collection and I have it mounted on a 12" high stand to provide a more comfortable sawing position.

I primarily use a 1/2" carbide blade with 4 teeth per inch. With the fence adjusted to compensate for drift, this setup is ideal for re-sawing.

Bill Henzel

Bill has a 20-inch Agazani saw with a 1-inch Woodmaster carbide blade for cutting veneers.

He also has a small Delta saw with narrow blades.

Ken Napior

Ken has a 3-1/2 hp 18-inch Rikon saw with either a 3/4 or 1-inch blade.

Burt Rosenzweig

I recently picked up the Craftsman bandsaw from Paul Norton. He was giving it away free, because it needed work. I had to replace the v-belt pulley that drives the lower wheel. The pulley was no longer available from Sears, but I got one from Grainger that works well. I had to replace the missing key for the keyway. I had to re-mount the motor V-belt pulley which was loose. I made a miter gage for the miter gage slot. I will be giving the saw to my daughter and son-in-law.

I inherited the 14" Delta bandsaw from my father about 25 years ago. It came with quite a few Delta blades. I relocated the on-off switch from the stand to the vertical column. I made an adapter for the dust port to fit my shop vac. I replaced the blade guide bearings, but otherwise it is all original. I bought the ¾" wide blade for re-sawing and it works great. I have the sanding belt kit, but have not used it on this saw. I put tennis balls on the ends of the fence rails so my wife and I don't injure ourselves when bending down to get the shoes that are beside the saw.

Lloyd Worthington-Levy

Lloyd has a Laguna 1412 with a Shopvac as a dust collector.

He uses it to cut veneer up to 8 inches wide and to resaw lumber.

This has been a great machine, especially for resawing stock.

I typically use Highland Wood Slicer blades and get good, clean cuts.

The dust collection port is well

positioned, and I attach it to a regular shop vac

Jamie Buxton

Jamie has a 16-inch Laguna which is from 1999.

The original table is too small so he added a fold down outfeed table.

It is a 16" floorstanding saw with a welded steel frame.

It generally wears a resaw blade with carbide teeth: a 1" Lenox Woodmaster CT.

I do have some smaller steel blades for cutting curves.

My one big complaint about the saw is that it has the same tiny table that all modern bandsaws have.

If I'm trying to rip or resaw anything longer than a couple feet, the workpiece is trying to fall off theback side.

My fix is an outfeed table mounted to the saw. It folds down when not in use.

I also added a plywood foot at the floor to prevent the saw from tipping over if I wildly overload the outfeed table.

Frank Ramsay

2 hp 17-inch Rikon with a 1/4 in. inch blade

Chess pawn cut on bandsaw

Triangular stock with Pawns and their push sticks

Vee block with pawn in cutting position

Jon Kaplan

Jon has a 14-inch Grizzly bandsaw with a 6-inch cutting height.

He uses 3/16 and 5/8 wide blades. He has had problems keeping the bearings clean and adjusting the guides.

Standard Grizzly 14" Saw - Plywood tall fence attachment for resawing.

Does the job well, but difficult to adjust the guides

And this thing eats bearing guides

Dennis Yamamoto

Rockwell 14"

110 VAC

1/2 HP

3/8" 6TPI blade

Minmax MM16 (imported by SCM, manufactured by Centauro)

220VAC, single phase

4.8 HP

1" 2/3TPI variable pitch Lenox tri-master

Used for resawing and cutting veneers

Minmax S600P or MM24 (imported by SCM, manufactured by Centauro)

Used for resawing and cutting veneers

220VAC, 3 phase

7.5 HP

24" resaw height

1" 1.3 TPI Lenox Woodmaster CT

Mark Hanrahan

Gillian Manufacturing kit

Ad for saw

Ad for saw

Mark, one of our Diablo Woodworkers guests,

has a saw which he built from a Gillian Manufacturing kit

that has metal parts and a plywood cabinet.

He uses it for cutting bowl blanks.

Tom Gaston

Tom has an 18-inch Makita saw with a 2-1/2-inch blade which he uses only to resaw.

It uses a geared down router motor so it is very noisy.

Bruce Powell

Newest but Oldest –a circa 1950's Craftsman Model 103.xxx

Donated by Dr. Torney in May 2020

it came w/o stand but with a motor

Shopfox14" bansdsaw in Groveland shop-very compact

good fence

built-in locking wheels

handles 3/4 in. blade

1 HP motor

Comparison between Inca and Craftsman bandsaws

Inca:

takes a 78" blade

has 3/4HP motor

has some dust collection

runs opposite to all other bandsaws

(need to flip blade!)

Craftsman:

takes a 80" blade

has 1/2 HP motor

no dust collection port

A bit deeper throat

All resawing done on Inca Model 640 benchtop in San Francisco

that has been a workhorse for 40+ years.

All the 6"X6" old-growth fir beams used to make the bending forms were also shaped on the Inca

(see presentation link for more details)

For more details Bruce's Presentation: Bruce

There followed a discussion of the merits of high-speed steel blades vs. carbide, blade lubrication, and re-sharpening of bandsaw blades.

Top

Show and Tell

Lloyd Worthington-Levy

Lloyd showed some COVID boxes with violin and cello pegs as handles.

They were finished with General Finishes water-based urethane.

Jon Kaplan

Jon showed a picture of a miter trimmer that he had purchased

a long time ago and just got around to trying out.

It seems to work very well.

He has also made a bunch of his walking hedgehogs for the toy drive.

Tom Gaston

Tom had minor hand surgery and so was only able to make

a beautiful mural out of birch bark this month.

Burt Rosenzweig

Burt made a steel and brass marking gauge

in his home shop using a metal lathe.

Jamie Buxton

in his home shop using a metal lathe.