President's Message

Fellow woodworkers,

A few Sundays ago I went to Schoenstein & Co., pipe organ builders, in Benicia to attend the celebration party for their newest organ project. It was a large pipe organ for the Ladue Chapel Presbyterian Church in St. Louis, Missouri. The organ has 46 ranks involving 2712 pipes.

At their facility they have this very high room where they can do a full assembly and test of an organ before it is dismantled and shipped to its home.

This organ was for a church and the left and right sides of the organ were assembled side by side with the console sitting quite a distance away. As the organ was not enclosed in behind a wall which it will be in its final location so you could walk in and around to see it from all angles. There were a couple of large blowers that feed several bellows which provide the air to the different chambers. Piping was everywhere, some of which was indistinguishable from the ducting in our workshops.

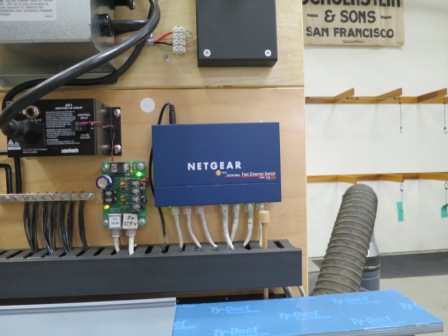

What surprised me is there were no major connections between the console and the sets of pipes – it was all electronic with the signals being sent via an Ethernet cable.

Some of the organs pipes were not in the assemble room as they are reusing one rank of large wooden pipes from the chapel's existing organ.

I had always been interested in old discarded wooden organ pipes, a good source of old, straight, grained wood. The pipes I acquired in England were Cedar. Traditionally, here on the West coast, they used Sugar Pine, but Sugar Pine is now scarce due to the destruction by the cone beetle a few years ago. At Schoenstien they are now using a different wood. There were heavily shellacked lengths of this new wood around the room. I looked at them but could not determine what they were. When I asked I was told it was Poplar – I never expected that such a basic wood would be used for such a magnificent function. They use Poplar as it is apparently cheaper and lighter than most other woods –maybe I will not be so keen to get these pipes when the organ is eventually retired. It is not all cheap wood; Maple is used for the mouths of the pipes.

It was also interesting to see the Schoenstein archive room. Not many companies today retain the tradition of maintaining archives. Their room has hundreds of books on organs plus the historic plans of the machines they have built and even the typewriters they used to use.

For more details on the organ: laduechapelorgan.wordpress.com

On a separate note I was sorry to hear from a BAWA member about the closing of Southern Lumber in San Jose the other week. It all seemed to have happened very fast and it was closed before I knew about it. It had an amazing collection of beautiful lumber, very expensive but when I need that special piece of Birds Eye Maple or something I would often go looking there. Usually ending up buying a little bit of some other exotic wood at the same time. It had been around for 110 years but when you own 3.4 acres of prime land near downtown San Jose there are much more valuable things you can do with it than use it for a lumber yard.

Enjoy your woodworking.

Frank (Contact at: Frankramsay8@aol.com)

President Frank Ramsay called the meeting to order at 7PM.

New Members and Guests:

New members Mike and Dan were introduced.

Announcements:

In Per's absence, Frank briefly went over the upcoming events.

On July 18th there will be a site visit to the Educational Tall Ships Project in Marin.

The August monthly meeting will take place at the factory of woodenwindows.com in Oakland. See the schedule on the website for details.

Neal has donated an oxy propane torch for silent auction. It was won by Arnie Champagne at the end of the meeting. Stan announced the availability of small parts boxes for silent auction. Don Naples spoke about his time as a member of BAWA, which he joined in 1982. He invented the Lap Sharp system of tool sharpening. He now lives in Healdsburg and spends his time making custom audio speakers using Orion drivers.

Stan announced the continuing raffle of a red oak and a maple board. Tickets are $1 each or 6/5$ and the raffle will take place when $100 of tickets are sold. For the door prizes, 3 tickets will be drawn at the end of the meeting.

Mike announced the availability of a dust collection hood to give away.

Jamie announced the 2x4 contest, which will take place at the October meeting. The only requirement is that the project be made from a single 8 foot long 2x4.

Ron Ashby from shellac.net.

Ron is an expert on finishing techniques, particularly in the use of shellac. His company, shellac.net sells everything from shellac flakes to solvents to brushes to tack cloths that you might need to finish a project. He began his talk by pointing out the importance of being able to see what you are doing.

Neal White showed the veneer hammer he has made and will show us what he has done with it in the future.

Many colors of shellac

Attentive crowd

The 3 basic layers of a finish are the base coat, the build coat, and the top coat. The base coat fills the pores in the wood and enhances the equal absorption of finish in the later layers. Dewaxed shellac is an excellent material to use here for later application of varnishes. If a spot sucks up the finish, let it cure before applying more finish so the first coat can plug the pores before the later coat is applied. One can also use a Behlen vinyl sealer for this purpose. The build coat should be a glossy finish, which will have the minimum number of adulterants. If you use a satin finish here, you will get multiple reflections at the boundaries between layers leading to a dull look. The top coat should be glossy and can be a good quality wax such as Renaissance wax/polish.

Shellac sticks

One can sand too much and begin to burnish rather than smooth the wood. 320 grit is good enough for most applications and the paper should not become hot while working. One can also use products such as pre-stain conditioners, which help to reduce splotching problems due to uneven finish absorption. One can use diluted dewaxed shellac (3/4 pound cut), or 9:1 diluted hide glue. Use of a good tack cloth just before applying finish is also highly recommended to remove any particles still imbedded in the surface. To get an antique look to the wood you can use potassium dichromate, which oxidizes the tannins in the wood to darken it. For a food safe finish use Behlen salad bowl finish. For a durable and tough finish for table tops use Behlen table top varnish. For this product you cannot allow more than 8 hours between coats, otherwise there will be adhesion problems, so you need to have a pre determined schedule for applying the finish to get it all done in time. There are a few tricks when using dyes and stains. One is to first apply a wash of dye diluted with DNA and then brush with full strength dye across the grain. This will give the most even color to the wood. One can also use non grain raising retarder to slow down the drying of a dye or stain.

And, finally, when a finish looks good enough it is necessary to apply one more coat. The effect will show up later on after the finish has aged for a while.

Following the break:

Bruce Powell talked about the marquetry class he took with Matt Werner in Scotts Valley. He brought in two examples of the work he did using 1/16 " thick veneer.

Andy Buteau showed a picture frame he made using inlaid butterfly keys to strengthen the miter joints.

Neal White showed the veneer hammer he has made and will show us what he has done with it in the future.

Ven asked for suggestions about where to acquire material to make a wizard's walking stick.

Jeff Dye asked for suggestions about how to deal with a white stain on a lacquered finish.

The meeting ended with the door prize raffle.

Steve RosenblumSecretary steve@rosenblums.us